Increasing productivity is not about making sweeping changes to your operation. It’s achieved through incremental improvements across technology, people, and process. Our Productivity Services help you to identify the biggest improvement opportunities for your business and to facilitate meaningful changes that will last. We offer a combination of software and professional services that will help increase the productivity of your workcell, workflow, and defects within existing processes.

Whether increasing asset utilization or uncovering new capacity, we will work with you to achieve more value from your investments, faster, and ensure you are managing your environment to its fullest potential.

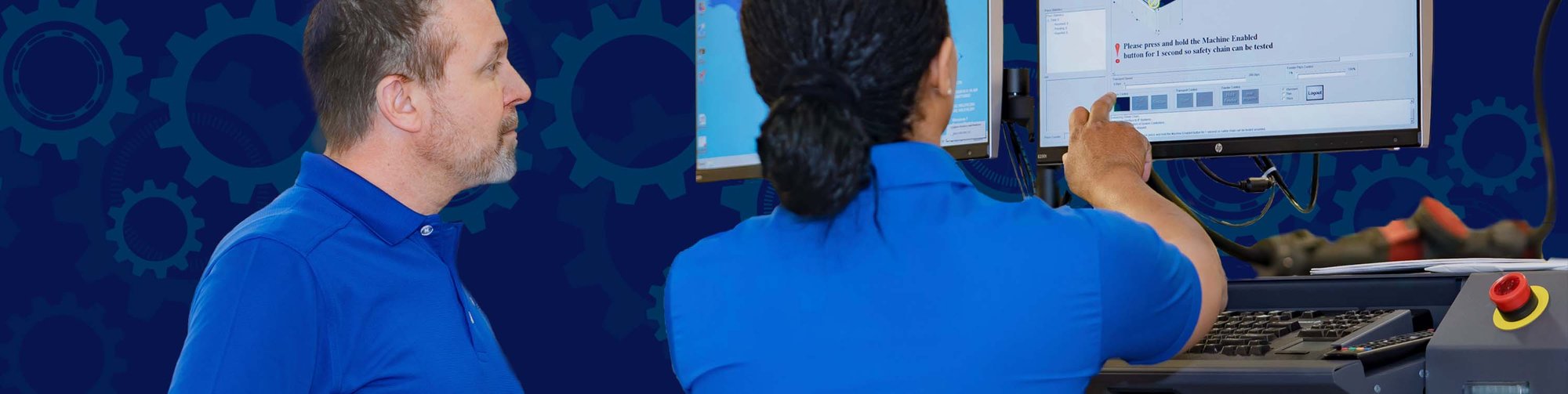

Our experts will assess your work cells, review your production process, and teach you how to effectively use data to create sustainable processes to improve performance and productivity. We will help you identify practical and effective development opportunities, that lead to immediate results.

Direct Connect (DC) Optimization

Direct Connect (DC) OptimizationWe help ensure that you are getting the most out of Direct Connect insights from your inserting systems, and how to use them to improve the productivity of both your machines and operators. Direct Connect provides real-time critical information needed to monitor work cell productivity related to idle time, non-productive time, machine, and application type is tracked, enabling production managers to proactively implement adjustments and immediately monitor results.

We use standard methodologies to identify the key loss areas of a work cell and establish resolution plans that drive rapid results and sustained improvement.

Our team will help the transition of new automated technology into your environment with ongoing support, coaching, and mentoring, to help you accelerate your time to results.

Looking at the holistic end-to-end workflow, our experts will identify opportunities to improve productivity and quality, resulting in lower operating costs.